3-D Pulp: Crop Residue At Small and Large Scales - UIUC Campus Research Board, $14,522 (2016)

This project was funded by the University of Illinois Campus Research Board in 2016.

Abstract

This project aims to foster new and continue existing collaboration in research and pedagogy between Associate Professor Eric Benson (Graphic Design), Associate Professor Mark Taylor (Architecture), and Assistant Professor Sameh Tawfick (Mechanical Science and Engineering) on using crop residue pulp (corn, soy, rye, miscanthus and prairie grasses, etc.) in three-dimensional forms. We will investigate the formation of truly “sustainable, ” compostable, or recyclable 3D printed, molded, and constructed forms from novel agri-fiber bio-plastic composites. We will use a Fused Deposition Modeling (FDM) 3D printer, slip-casting molds, and other molding techniques to create three-dimensional forms in different scales (from smaller 3D printed objects to larger architectural scale artifacts). The mechanical strength and density of the forms will be studied and related to the intrinsic agri-fiber properties to establish a processing-structure-property relationship. Finally, the team will study the consequent potential applications of each variety of fiber in the third dimension, and how the results can influence and improve further research into crop residue and also enhance existing course projects in design, architecture, and engineering.

Results

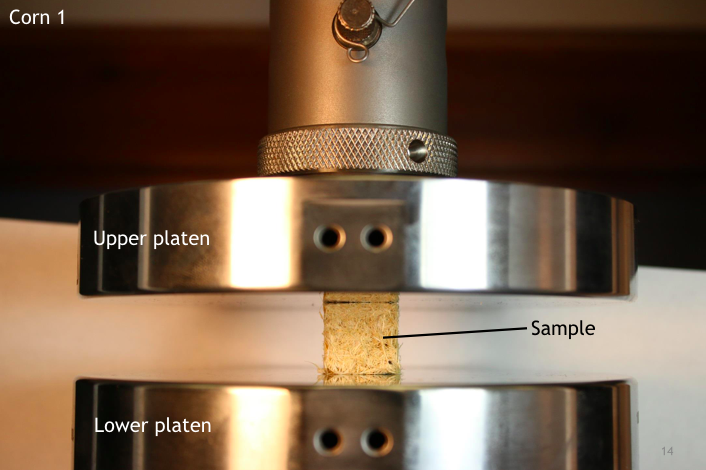

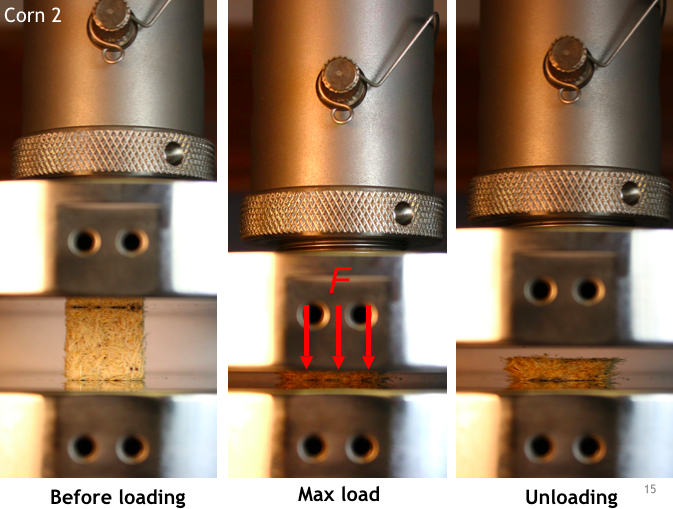

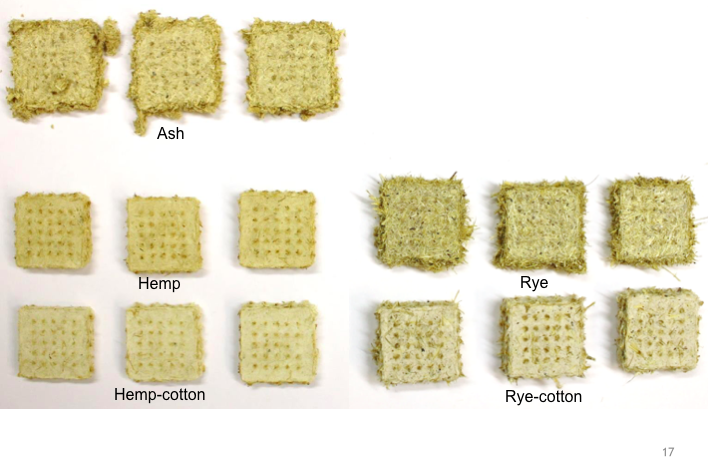

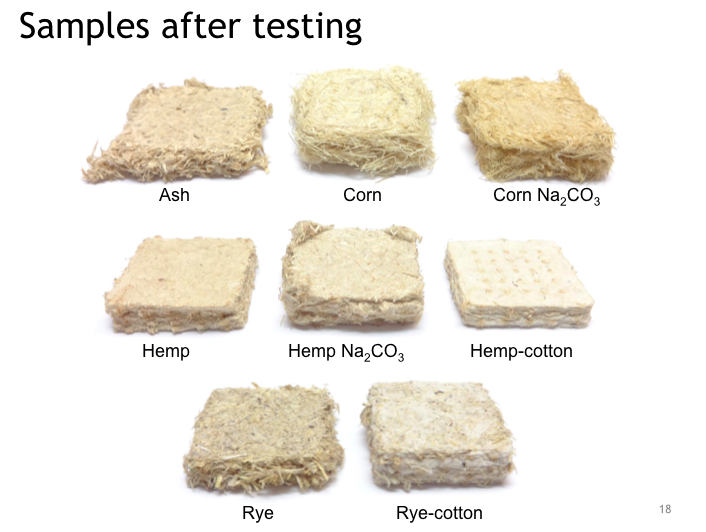

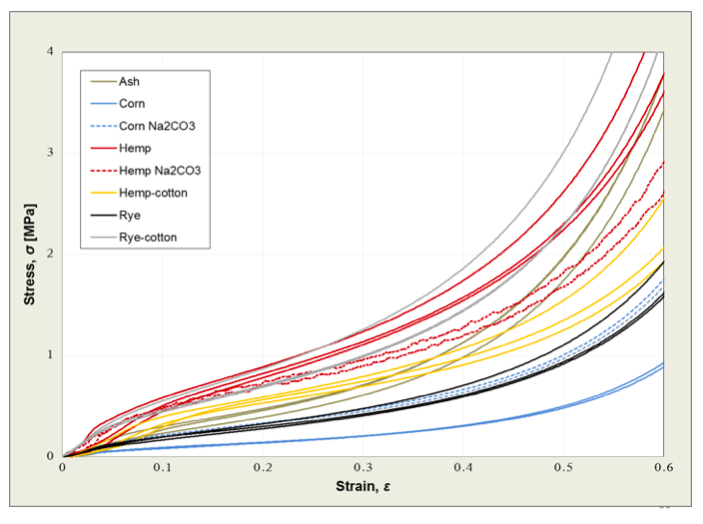

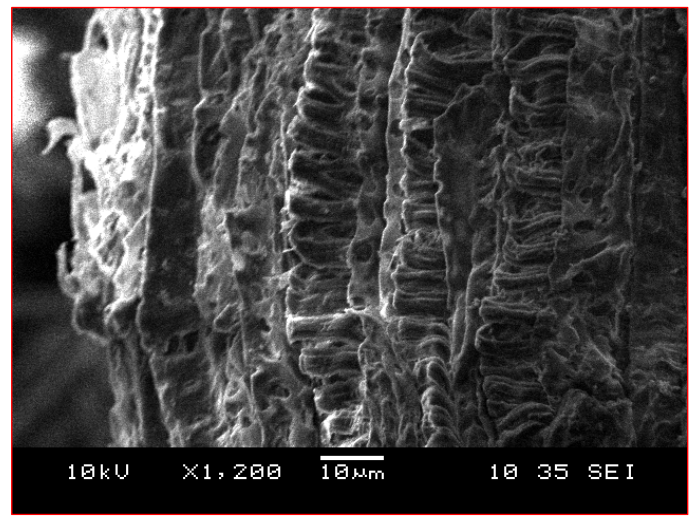

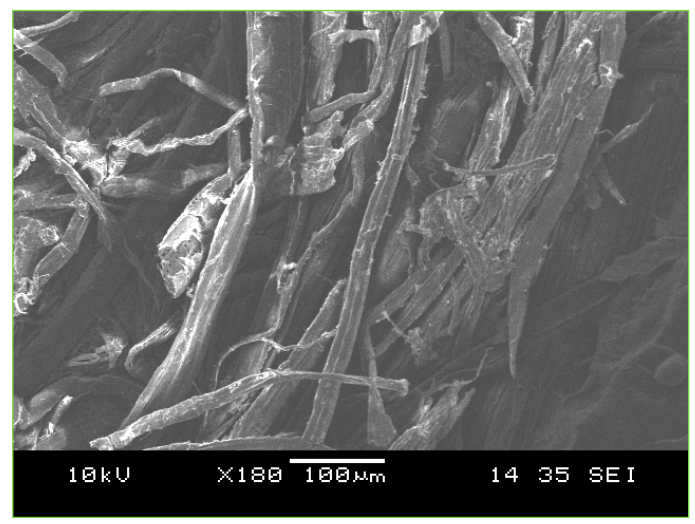

During the timeframe in which our team was funded by the Campus Research Board, we successfully tested beaten corn, hemp, cotton, rye, and ash tree fiber characteristics in their three-dimensional form. These agricultural fibers were tested based on data from a previous set of tests done a few years earlier by Dr. Tawfick and Professor Benson. These agricultural fibers were beaten at Fresh Press Agri-Fiber Paper Lab on campus and then placed in multiple 3-D printed molds to be tested for: dry mass, volume, density, strength, and stiffness. These fibers were also photographed under a SEM and the data from these tests told us a great deal about which fibers to further explore and could hold promise for any commercial paper products like packaging or insulation.

Connected to this research, a member of our team, Professor Mark Taylor explored hemp, miscanthus, and corn as a building and insulation material for architecture. He collaborated outside of the grant with another faculty member in engineering to test the r factor for these materials for insulation and created larger bricks (than our previous cubes) to strength test as building materials for walls and beyond.

In April 2018 two letters of interest were submitted in response to Arup’s Global Research Challenge, one drew on the research into the properties and potential of bio-fibers, the second was titled “Maximizing the Social Benefits of Geopolymers in the Built Environment”. The second of these two letters is particularly interesting: “The potential use of Geopolymers is vast, ranging from water purification and desalination; renewable energy storage of phase change materials for electricity generation; airport runways; acid resistant sewage pipe linings; building construction materials for earthquake resistant structures; flame resistant insulation, and the creation of ultra tall wind turbines.”

All images above are by Lauren Kovanko.

Publications

Taylor, Mark, Benson, Eric, and Tawfick, Sam. “Agri-fiber in 3-Dimensions,” World Multidisciplinary Civil Engineering-Architecture-Urban Planning Symposium, June 18-22, 2018, Prague, Czech Republic.